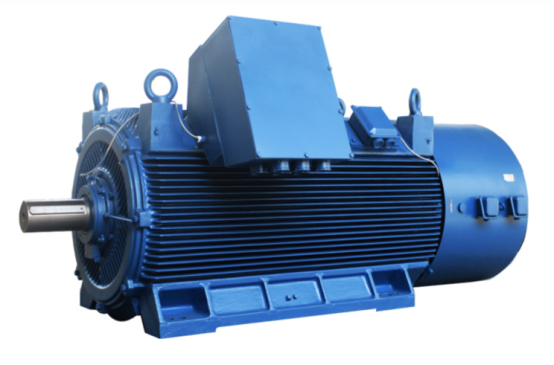

YVFZ three phase AC motor

Voltage 380V (400-450mm), 660V (500-560mm)

Cooling method IC416 (independent axial fan, or centrifugal fan)

Independent fan voltage three-phase, 380V

Working method S3-40% for lifting and metallurgy

Altitude does not exceed 1000m

High-precision rotor balancing system greatly reduces motor vibration and noise.

The bearing is equipped with a non-stop refueling device.

This series of motors have the characteristics of large overload capacity..

Application industry Driven equipment

Steel rolling mill, coiling machine, balancing machine, tension machine, shearing machine

Oil pumping unit, oil and gas transportation, drilling rig

Power plant Induced draft fan, feed water pump, coal conveyor

Marine boilers, compressors, thrusters

Pulp making machine, extrusion machine

Variable speed system experiment generator

Rubber and plastic mixer, extruder